-

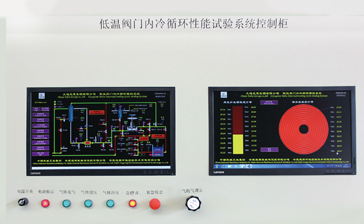

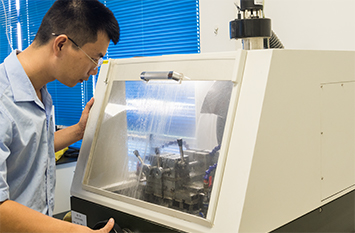

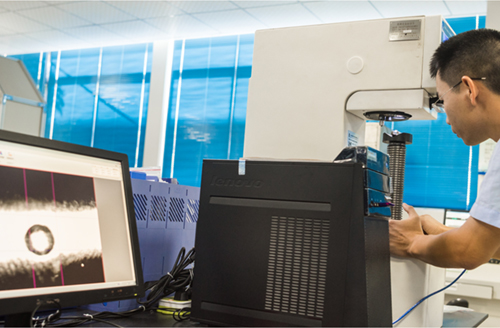

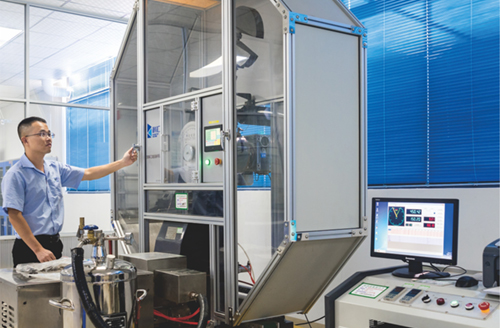

The Chase Valve Manufacturing Group covers the Vertical Integration of industrial valve manufacturing and application of Integrated Service System, from the Valve R&D Design, Forging, Casting, Valve Actuator Manufacturing, Valve Machining and Manufacturing Processes which fully realized from the raw materials to final products are completed within the company. The One Stop Business Mode ensures the most critical Quality Standards form the source and raw materials. The Chase Valve Group has expert-level R&D team from Italy, Germany, Taiwan and other countries & area as well as professional manufacturing technology of valves. The Mission of The Chase Valve Group Is to create new castings with unique characteristics, new material development and professional valve processing & manufacturing to realize the valve products with special devices and critical working conditions designed and manufactured in China.

Intelligent Creation Innovates Dreams

Home page

Home page